Our exclusive two-stage stretch-break converter technology

875 Stretch-Break Converter

The Type 875 stretch-break machine is suitable for converting all tow types offering variable and reproducible fibre diagrams. The main fibres processed are acrylic (PAN), polyester (PES), polypropylene (PP) and viscose (CV).

Functionality

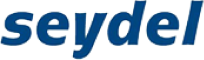

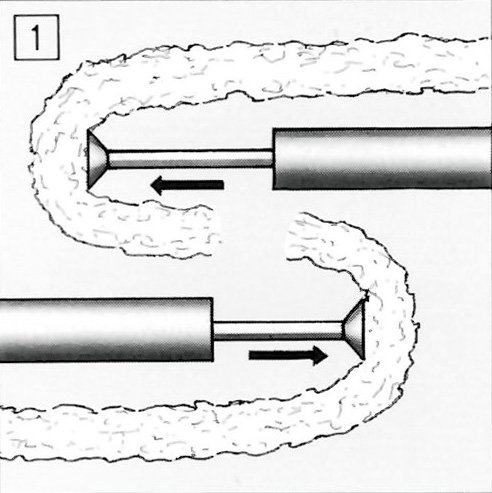

Through the breaking process, the machine converts filament tow into slivers, having a staple diagram similar to wool.

A special TRIO and QUATTRO tow deflection system, in a solid cast iron construction, achieves ideal stretching and fibre length related conditions. The material is pre-stretched in the first breaking zone, while post-breaking and fibre diagram optimization occurs in the second zone. Optimum fibre diagrams are achieved thanks to the adjustable breaking distances of the last 3 breaking zones.

Main Features

- Minimal space requirement

- Simplified construction

- Easy accessibility

Components

The converter comes with these special components for smooth production:

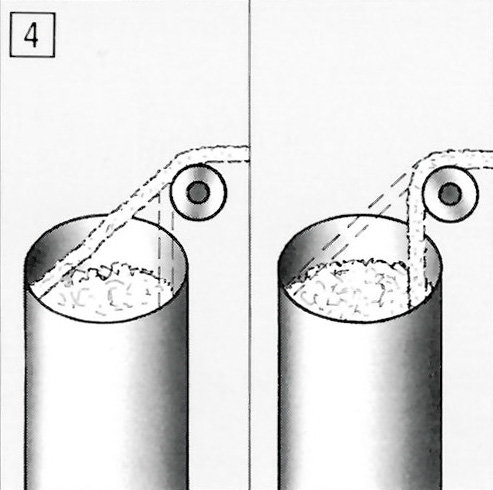

Sliver detacher

The sliver detacher enables the slivers to be separated without problem during the can doffing. The automatic can change works simply and without operator intervention.

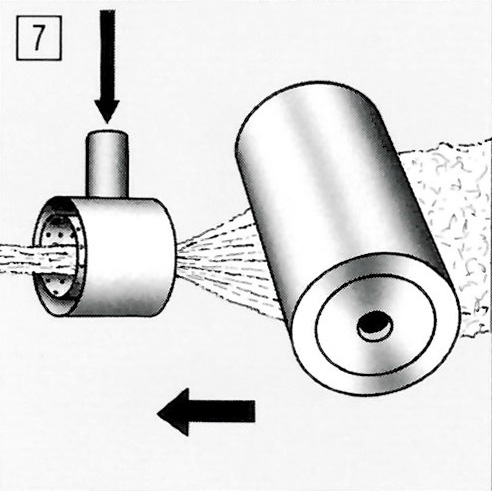

Cooling belt conveyor

The cooling belt conveyor with built-in suction prevents the material from further shrinkage.

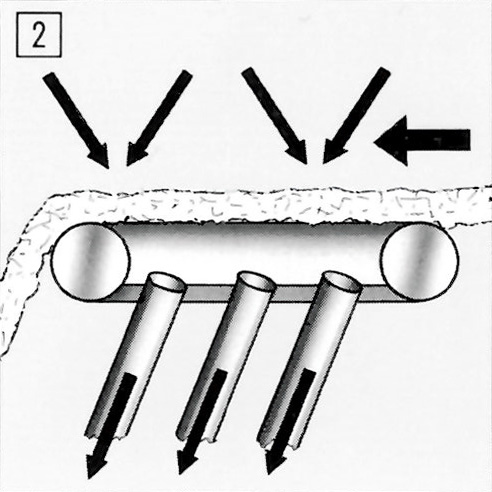

Can doffer

The automatic can change and doffing is available in different versions.

Sliver layer

The sliver layer ensures that the cans are evenly filled. Necessary for cans with large diameters.

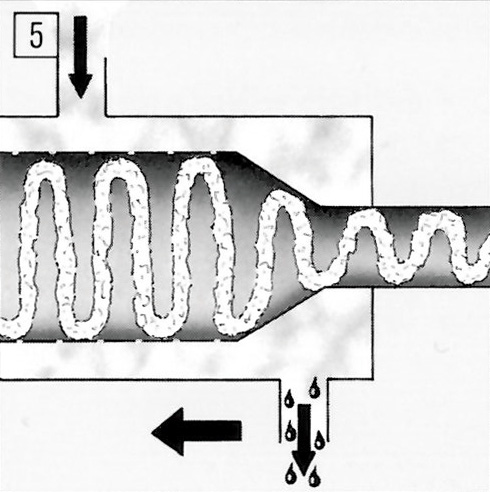

Steam relaxer

The steam chamber relaxes and sets the sliver. The fibres are treated gently with low energy consumption.

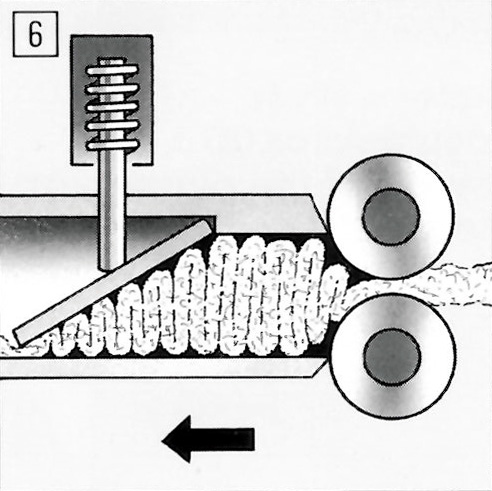

Crimper box

The crimper box compresses the tow to the desired quality by means of pneumatic adjustment.

Sliver compactor

The sliver compactor enables fibre cohesion, which avoids subsequent fibre separation. The newly developed infeed assures good operation and results